Protocolo Operacional Padrão: Complete Guide for Organizations and Businesses

The protocolo operacional padrão (POP), or Standard Operating Procedure (SOP), is a crucial tool for businesses and organizations seeking consistency, efficiency, and safety in their operations. It consists of a detailed set of guidelines that instruct employees on how to perform specific tasks, reducing errors and improving productivity. This comprehensive guide explains the concept, importance, structure, and implementation of protocolo operacional padrão, along with tips for creating and applying them effectively. By following POPs, organizations ensure that all team members perform tasks in a consistent, reliable, and compliant manner.

What is Protocolo Operacional Padrão?

The protocolo operacional padrão is a formal document that provides step-by-step instructions for performing specific activities. Its purpose is to ensure that tasks are executed consistently and accurately, regardless of who performs them.

POPs are widely used in various industries, including manufacturing, healthcare, logistics, education, and technology, to standardize operations, reduce errors, and maintain high-quality outcomes. By documenting processes clearly, organizations can monitor performance, identify inefficiencies, and implement continuous improvement strategies.

Why Protocolo Operacional Padrão is Important

Ensures Consistency

One of the main advantages of a protocolo operacional padrão is that it ensures uniformity across operations. When all employees follow the same instructions, organizations maintain consistent quality and prevent variations that could negatively affect results.

Reduces Errors

By providing detailed instructions, POPs help minimize human error, reducing waste, rework, and operational mistakes. This is particularly critical in environments where precision and safety are vital, such as hospitals, laboratories, and manufacturing facilities.

Facilitates Employee Training

A well-documented POP serves as a reference manual for training new staff. Employees can quickly learn the correct procedures, reduce onboarding time, and become productive faster.

Supports Continuous Improvement

Documenting processes allows organizations to identify areas for improvement, refine operations, and increase efficiency, safety, and overall performance.

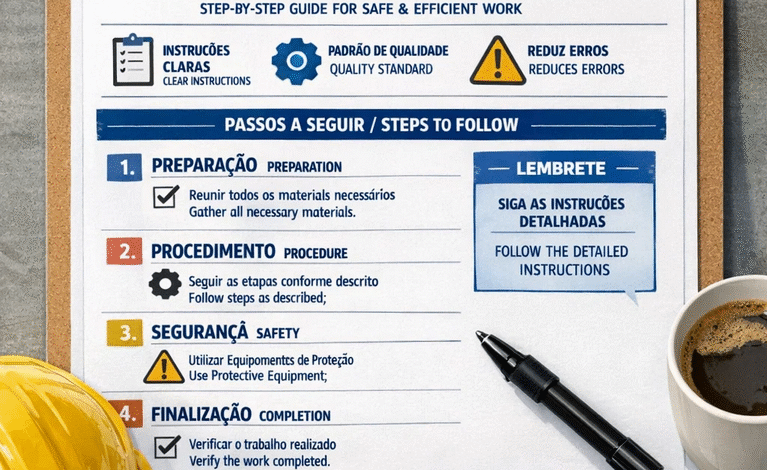

Key Components of a Protocolo Operacional Padrão

A well-structured POP contains several essential elements that ensure clarity and usability:

Title of the Procedure

Clearly indicates the activity or process the POP covers.

Objective

Explains the purpose of the procedure and the expected outcomes.

Scope

Specifies which departments, roles, or employees must follow the protocol.

Responsibilities

Defines who is accountable for each step of the process.

Materials and Equipment

Lists all resources required to perform the task efficiently.

Step-by-Step Instructions

Provides detailed, numbered instructions for completing the process accurately.

Safety Measures

Includes potential risks and safety precautions to protect employees and ensure compliance.

References and Appendices

Includes additional documentation, forms, or templates that support the procedure.

How to Develop a Protocolo Operacional Padrão

Step 1: Identify the Process

Begin by identifying the critical task or process that requires standardization. This could be related to production, administration, or customer service.

Step 2: Map Each Step

Document every step in the process sequentially and clearly. Mapping helps visualize the workflow, identify redundancies, and define responsibilities.

Step 3: Define Quality Standards

Establish measurable criteria for task performance, ensuring that employees understand what successful completion looks like.

Step 4: Review and Validate

Have experts review the POP and test it in practice. This ensures that instructions are accurate, understandable, and applicable in real situations.

Step 5: Train and Implement

Provide training sessions to familiarize employees with the POP. Monitor its implementation and make adjustments based on feedback or operational changes.

Applications of Protocolo Operacional Padrão

Manufacturing Industry

In manufacturing, POPs standardize production lines, machinery operations, and quality control, minimizing errors and increasing efficiency. Detailed procedures help maintain uniform product quality and prevent operational hazards.

Healthcare Sector

Hospitals and clinics use POPs for medical procedures, patient care, and medication administration. Following these protocols ensures patient safety, regulatory compliance, and error prevention.

Logistics and Supply Chain

Logistics companies use POPs for receiving, storing, and shipping products, ensuring accurate inventory management and timely delivery. Standardized procedures improve traceability and operational efficiency.

Educational Institutions

Schools and universities can implement POPs for administrative and academic procedures, such as enrollment, grading, and student safety, ensuring consistent execution and compliance across staff and departments.

Benefits of Standardizing Operations with POP

Improved Productivity

Standardized processes allow employees to work more efficiently and consistently, reducing mistakes and duplication of effort.

Enhanced Safety

By including safety protocols and preventive measures, POPs help create a safer work environment and reduce workplace accidents.

Ease of Compliance and Auditing

Organizations following POPs maintain clear documentation, facilitating audits, inspections, and adherence to regulatory standards.

Continuous Improvement and Innovation

POPs enable organizations to identify inefficiencies, streamline processes, and innovate by refining procedures over time.

Challenges in Implementing POPs

Resistance to Change

Employees may resist following standardized procedures if they feel restricted or overburdened by rules. Involving staff in developing POPs and providing proper training helps overcome this barrier.

Continuous Updates Required

Processes evolve over time. A POPs that are outdated can cause confusion or errors. Regular reviews and updates are essential to maintain relevance.

Excessive Complexity

Overly detailed POPs can become difficult to understand or apply. Balance detail with clarity, ensuring the protocol remains practical and user-friendly.

Best Practices for Effective POPs

- Be Clear and Objective: Use simple, precise language to avoid ambiguity.

- Use Visual Aids: Flowcharts, diagrams, and tables improve comprehension.

- Assign Responsibilities: Clearly indicate who is responsible for each step.

- Include Safety Guidelines: Highlight risks and preventive measures.

- Review Periodically: Update POPs based on process changes or improvements.

Following these practices ensures that POPs are effective, practical, and beneficial for both employees and the organization.

Conclusion

The protocolo operacional padrão is a strategic tool that ensures consistency, quality, and safety in organizational operations. By documenting procedures, reducing errors, and providing a clear reference for employees, POPs enhance productivity, training efficiency, and continuous improvement.

When implemented effectively, a POP helps organizations achieve operational excellence, maintain compliance, and improve overall performance. Regular updates, clear instructions, and proper training are essential to maximizing the benefits of these protocols.

FAQs

1. What is protocolo operacional padrão?

It is a document that provides step-by-step instructions for performing tasks, ensuring consistency and quality.

2. Why is implementing POP important?

It reduces errors, increases productivity, ensures safety, and supports compliance with regulations.

3. Which industries use POPs?

POPs are used in manufacturing, healthcare, logistics, education, and virtually any organization needing standardized processes.

4. How should a POP be developed?

Identify the process, map steps, define quality standards, review, validate, train staff, and implement.

5. How often should POPs be updated?

POPs should be reviewed periodically, especially when processes, regulations, or operational requirements change.

6. Does a POP replace training?

No. It complements training by serving as a reference manual and standardizing procedures.

7. What are the benefits of standardizing processes with POP?

It improves productivity, safety, audit readiness, and supports continuous improvement across the organization.

Get more updates or Stories on Next Magazine